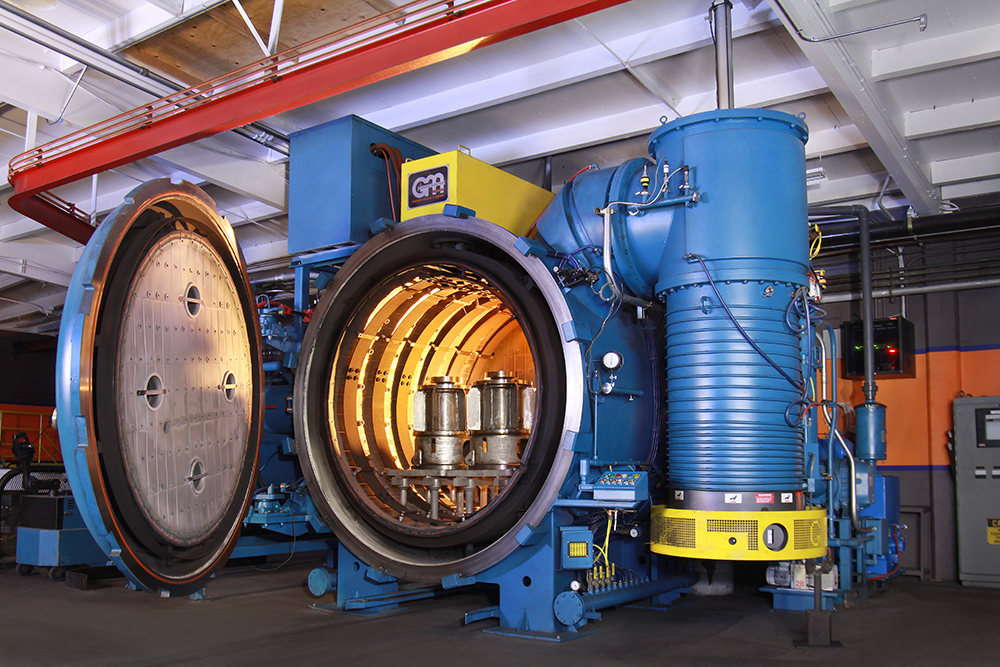

Our heat treatment process for air hardening steel is first done in our vacuum furnaces. The vacuum helps keep the surface finish and appearance on the steel, while at the same time minimizing the oxide, scale and decarburization of the blade. The blades are control quenched in a partial vacuum with pure Nitrogen gas to ensure air quench properties are met while minimizing any surface contamination. An optional addition to the process is cryo treatment following the quench, where we submerge the blades into a subzero temperature environment to stabilize the blade and eliminate retained austenite. We will follow up with tempering the blade to a final hardness, and offer the option of providing a second temper to help ensure a uniform temper throughout the blade to the desired hardness. Following this, we offer a straightening service option buy experienced workers with advanced equipment to ensure minimal warping and bends in the final product. We test and report the hardness on the appropriate scale and if desired can provide certification of the heat treatment process as well as a final hardness.

Our heat treatment process for air hardening steel is first done in our vacuum furnaces. The vacuum helps keep the surface finish and appearance on the steel, while at the same time minimizing the oxide, scale and decarburization of the blade. The blades are control quenched in a partial vacuum with pure Nitrogen gas to ensure air quench properties are met while minimizing any surface contamination. An optional addition to the process is cryo treatment following the quench, where we submerge the blades into a subzero temperature environment to stabilize the blade and eliminate retained austenite. We will follow up with tempering the blade to a final hardness, and offer the option of providing a second temper to help ensure a uniform temper throughout the blade to the desired hardness. Following this, we offer a straightening service option buy experienced workers with advanced equipment to ensure minimal warping and bends in the final product. We test and report the hardness on the appropriate scale and if desired can provide certification of the heat treatment process as well as a final hardness.

Air Hardening Steel earns its name from being hardened by cooling in air after being at high temperature. These steels are usually designated by the letter “A” followed by a number to designate their specific composition or properties in the air hardening category. The most common tool steel we will see at Byington is A-2 tool steels. Air hardening steels brag to have low distortion in heat treatment and has very high levels of wear resistance, making them a solid choice for blade material.

Air Hardening Steel earns its name from being hardened by cooling in air after being at high temperature. These steels are usually designated by the letter “A” followed by a number to designate their specific composition or properties in the air hardening category. The most common tool steel we will see at Byington is A-2 tool steels. Air hardening steels brag to have low distortion in heat treatment and has very high levels of wear resistance, making them a solid choice for blade material.

Proper heat treating of air hardening steels is important because it ensures the full properties of the steel are achieved. Improper heat treatment can lead to cracking, brittle blades, distortion, poor tempering, or something known as retained austenite. Retained austenite is essentially soft steel that results from improper heat treating, which can result in the steel warping or wear out more quickly. At Byington Steel our cryogenic equipment, furnaces for hardening and tempering, and experience can minimize all of these risks.